|

Blowholes

The first thing to do is to make a plan. This is probably the

most important part of your project. If your plan sucks, the

results you get will suck too. Decide witch fan brand and size

you are going to use. I always recommend getting the biggest

fan you can afford (that will fit where you want it of course).

The reason for this is that bigger fans always have better performance/noise

ratio. Once you have your fans, make sure that they will fit

where you want them. For example, if you mount them on a side

panel, make sure that you will be able to close that panel once

your modification is done. Also, keep in mind that a fan need

some place behind and in the front to breath well. If you don't

give it enough space, the fan will not work as good as it could

and you will get some additional noise. In this example, I'll

be using 120x38mm YSTech fans witch I got from Nerdsbyte.

Next

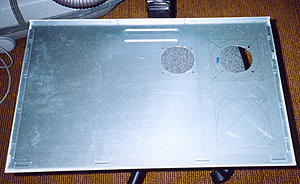

thing to do is to mark your blowhole. The best way to do so

is probably to tape the fan where you want it and use it as

a stencil. If you have a chrome fan guard, it will work even

better as a stencil since it weighs less. Always work from the

inside off your case if possible and use a lead pen. That way

you can easily clean your marks once the hole is done. Here

is a picture of my side panel with all the marks done.

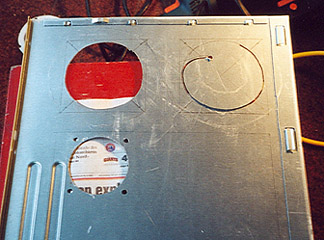

Now

comes the time to cut. A lot of people use a dremel to cut the

metal. If you do so, make sure you have a very powerful one

(30k to 35k rpm). Mine is a cheap one-which works with batteries

and only spin at 18k rpm. It would have taken me hours (and

a bunch of battery recharges) to cut these holes with my dermal

so I decided to use my good old jigsaw. Armed with a metal blade,

this thing can cut through anything. If you ask me, a whole

saw would probably give you the best results but they are pretty

expensive and you will need one for every size you need. Here

is a picture of the cutting process.

Next

>>

<<

Previous

|