|

These

are the most challenging blowholes I have done. 60mm holes

would of been pretty hard to do with a jigsaw so I used

a hole saw. It was much harder to cut through the case

than the window. Of course, metal offers much more resistance

than plastic. Several times during the process smoke was

coming out of my drill so I had to let it cool in order

to proceed.

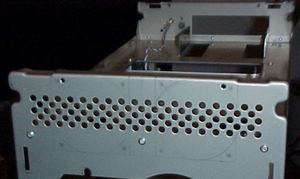

On

the picture above you can see the first blowhole about

halfway done. While I took this picture my drill was chilling

outside in the snow, that's one advantage of Canadian

winters… On the next picture you can see both blowholes

done. However the edges are very rough and require a serious

cleaning job. Again, a dremel is the best tool for this.

As

you can see on the previous picture, I needed to make

some place for the fans inside the case. There is a metal

plate separating the middle and upper sections of the

case that is in the way. Here's how I did it in three

steps with the help of my dremel, a metal cutter and a

lot of cursing.

Next

>>

<<

Previous

|